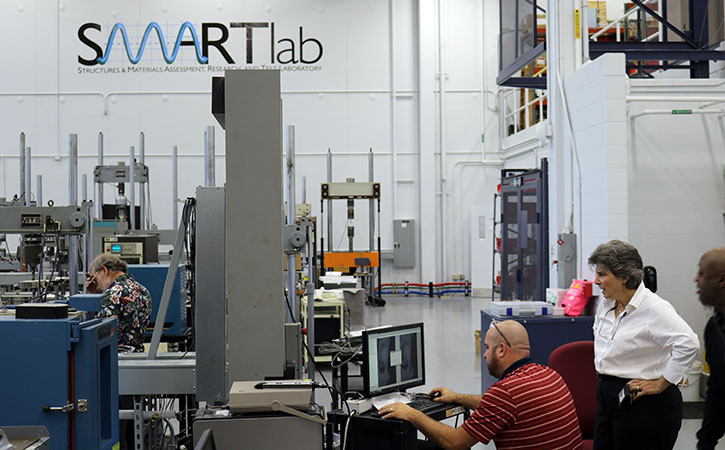

SMART Lab

New lab allows for larger structures, traditional testing under one roof

New lab allows for larger structures, traditional testing under one roof

Sometimes, size matters. The University of Dayton Research Institute’s new large-structure research and testing facility will allow researchers to grow their structural testing capabilities – literally as well as technically.

The Structures and Materials Assessment, Research and Testing (SMART) lab, which features 12,000 square feet of floor space and a nearly 40-foot floor-to-ceiling clearance, will permit researchers to test significantly larger structures – think small passenger plane – than they can currently accommodate in the high-bay test space next door at UDRI’s Shroyer Park Center on Firwood Avenue in Dayton. The lab also features a 20-by-20, 10-foot-deep floor pit to provide additional clearance for very tall structures, as well as 5- and 10-ton overhead cranes for heavy-duty lifting (see brochure).

“There have been times when customers have sought bids for testing very large structures, such as a full tail assembly from a cargo jet, and we couldn’t bid on the work because we simply didn’t have the room, said Mike Bouchard, head of the Aerospace Mechanics division. “This new lab will allow us to go after a much bigger variety of work, no pun intended. We’ll be able to test everything from a small material sample all the way up to and including an entire vehicle, even a small aircraft.”

Structural Integrity division head John Ruschau said structural testing is designed to evaluate how a structure or material behaves under stress. Test items are secured in test beds or rigs that will push, pull, bend, twist, vibrate, bake, humidify and/or otherwise stress the parts in ways that mimic the types of stress they will encounter during actual use, allowing researchers to see how well they hold up.

“We simulate realistic service conditions to help customers understand whether their parts and materials are strong and durable enough to withstand the repeated loads and harsh environments they will regularly experience in the field,” said Ruschau, whose researchers regularly perform fatigue testing on materials and structures for Department of Defense and commercial clients.

Structural testing also yields valuable information that helps sponsors better maintain existing assets, develop new products, or choose the best material for each specific application, said Bouchard, whose division is currently working with General Atomics Systems Integration to test the nose and main landing gear from a C-130 cargo plane – a test UDRI would not have been able to pursue prior to the addition of the SMART lab.

The landing gear of a cargo aircraft, which frequently cycles through take-offs, landings and taxiing, endure a great deal of stress, Bouchard said. UDRI researchers will install and calibrate sensors on the landing gear fixed to a large frame in the SMART lab before they are installed on the cargo craft, then participate in flight testing to help General Atomics understand the forces the gear are experiencing in service and whether they are showing signs of fatigue or failure.

The Research Institute has performed structures and materials assessment for six decades and developed significant expertise and renown in both areas, Ruschau said. “We’re equipped to offer customers specialized and even unique testing that we can customize to their needs, and the addition of new equipment and larger test beds in the SMART lab will allow us to expand those activities.”

UDRI’s sulky test rig is a good example of unique and customized structural testing, Ruschau said. The Research Institute is the only organization in the world which qualifies sulkies to race in U.S. Trotting Association-sanctioned harness racing (see video).

The need for such testing arose about 25 years ago, when sulky manufacturers began replacing aluminum and steel frames with lighter-weight composites, and the USTA wanted to ensure the frames could withstand the punishment they would take on the track, Ruschau said. Because no test existed to qualify the carts, UDRI researchers went to a racetrack, laptop and sensors in hand, and rigged a cart to record its every bounce, bump and strain as it was pulled behind a horse. “They brought that data back to the lab and designed and built a test rig that would recreate the same stress and load the cart had experienced on the track.”

Prototypes for new sulky designs are still routinely brought to UDRI; those that withstand the rigorous fatigue test are certified for mass manufacture and sale, said Ruschau, adding that UDRI regularly performs similar independent field-qualification of aircraft and commercial vehicle materials and designs for customers whose products must meet standards set by the Federal Aviation Administration, Department of Transportation, Air Force or other organization.

April 7, 2016