Coatings, Corrosion, and Erosion

Research to Protect, Prevent, and Preserve

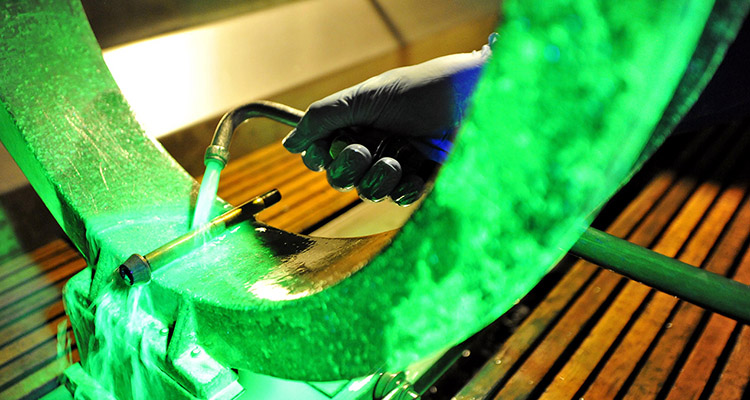

Applied Corrosion Technologies

UDRI specializes in aerospace coatings and corrosion-related process management and material development, evaluation, integration, and sustainment.

Capabilities

- Accelerated environmental weathering

- Application-specific technology/process improvements

- Specimen design and preparation

- Test planning and execution

- User collaboration

Our work focuses on environmentally desirable coating removal processes, better understanding asset condition based on cumulative exposure, promoting the use of mission- and cost-effective alternative coatings and application processes, and establishing Air-Force-level technical guidance for aircraft, ground equipment, and electronics corrosion prevention and control. We provide subject matter expertise in cradle-to-grave corrosion prevention and control of legacy and emerging systems.

Contact Us: 937-229-2113 | E-Mail | Form

Coatings, Corrosion, and Erosion

UDRI also evaluates coatings and solves paint problems for government and industry. We develop and test novel coatings technologies all the way to implementation and sustainment of these materials in the military and commercial sectors. We are ISO 17025 and SAE AS 5505 accredited for the application, testing, and performance characterization of organic coatings.

Capabilities

- Using standard and custom-designed protocols

- Qualifying coatings to present industry and aerospace standards

- Developing and transitioning novel coatings to commercial use

- Evaluating and analyzing corrosion on various substrates

UDRI operates four erosion facilities at Wright-Patterson Air Force Base: the Particle Erosion Test Facility, Rain Erosion Test Facility, Supersonic Rain Erosion (SuRE) test and evaluation apparatus, and Hot Particle Environmental Particulate Impact Test Facility. Commercial and industrial customers can take advantage of the state-of-the-art coatings application, research, development, verification and qualification and testing, corrosion assessment and analysis, and erosion testing facilities through Cooperative Research and Development Agreements (CRADAs).

Contact Us: 937-229-2113 | E-Mail | Form

Corrosion Science and Engineering

UDRI uses the Scanning Kelvin Probe (SKP) technique to characterize microbially influenced corrosion and degradation of coating systems in aircraft and is developing a field prototype of an SKP system for the US Air Force. Our researchers perform surface characterization (electrochemistry, SEM-EDS, and scanning probe techniques) of various metal substrates to support development of a condition-based maintenance corrosion damage model for aluminum alloys.

Capabilities

- Accelerated Corrosion Testing

- Atmospheric Corrosion Testing

- Analysis of Failure Due to Corrosion/Root Cause Determination

- Biomedical Device Corrosion

- Biopolymers/Environmentally Friendly Corrosion Inhibitors and Coatings

- Electrochemical Characterization of Coatings

- Electrochemical Engineering

- Surface Characterization