Machine Learning

Systems that Adapt and Adjust

According to American computing pioneer Arthur Samuel, machine learning is the ability of computers "to learn without being explicitly programmed." Machine learning is useful in computing tasks where designing and programming explicit algorithms with good performance is difficult or unfeasible; example applications include e-mail filtering, network intrusion or data breach detection, optical character recognition (OCR), and computer vision.

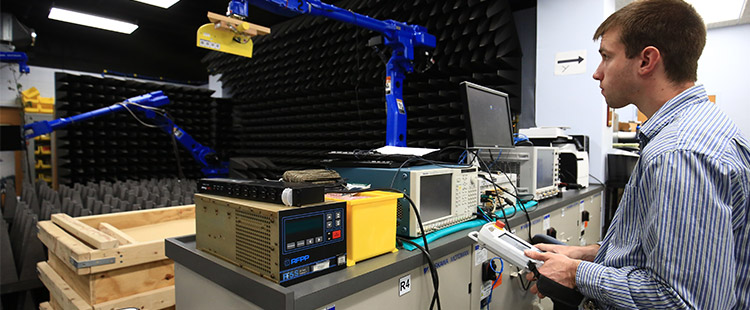

UDRI researchers develop and implement flexible systems that automatically adjust to the needs of users according to the input they provide. Our systems see connections between data sources and user inputs, and use these connections to map to a desired output. These outputs can be object labels (i.e. hammer, screwdriver, etc.), quality inferences (i.e. good, bad, high-porosity), or numeric values (i.e. predicted demand, quality score, etc.). These systems learn from user data to deduce solutions to complex problems.

UDRI-developed machine learning algorithms improve user awareness of available data, suggest areas for further investigation, and make connections between users and information to ensure analyses have more breadth and depth than a single user working alone. Our systems learn to understand how data products are developed, foster outside-the-box learning for users, and improve workflows.

Capabilities

Automation

- Vision based systems to verify the location of manufacturing line tools that perform specific tasks

Natural Language Processing

- Internet of Things (IoT) systems that centralize and manage HVAC system data from across machines and sensors from any manufacturer; pulling all data into a common format despite non-standardized data register names on each connected device (IOT device code translation)

Quality Assurance

- Detection and characterization of Coordinate Measuring Machine (CMM) probes using deep networks for improved quality assurance of machined parts

- Machine learning methodologies that analyze imagery of additive manufacturing processes and detect distortions or detachments that would result in a failed build

- Monitoring of manufacturing processes and predicting part quality accurately via trained convolution neural networks (CNNs) based on thermal imagery

Risk Prediction and Data Correlation

- Systems that identify risks to the supply chain such as availability of critical components or the credit worthiness of suppliers. The tool uses a combination of neural networks, Bayesian networks, and logical heuristics to identify failure points and correlate risks to part, supplier, and event (such as severe weather) features

Surveillance

- Systems utilizing sensor interoperability and an applied CNN to analyze captured images and assess the presence of activity in a given image

- Video summarization to consume and organize large volumes of video data by leveraging computer vision, audio processing, and natural language processing technologies; this capability fuses information from imagery and audio in order to infer delivery method, context, content, intent and pedigree

- Web-based situational awareness systems that aggregate, analyze, and monitor community or facility incident-related data using computer vision and deep learning technologies for object/person detection, activity recognition, and entity extraction